| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : RONGSHENG

Model Number : 10101-52-7

Certification : ISO9001

Place of Origin : Henan, China

Fire Resistance : Non-combustible

Type : Various size high working temperature

Length : 3600-7200mm

Tempreture : 1260

Shape : Ceramic Fiber Blanket

Chemical Content : Al2O3+SiO2

Chemical Composition : Al2O3-SiO2

Color : White

Thermal Conductivity : 0.09-0.16W/m·K

Colour : white

Bulk Density : 96-160kg/m3 or customized

Fiber Diameter : 5um

Compressive Strength : 0.08MPa

Temperature : 1260C

Package : braided bag/carton

1260 refractory ceramic fiber board thermal insulation aluminum silicate board heat resistant material for industrial furnace

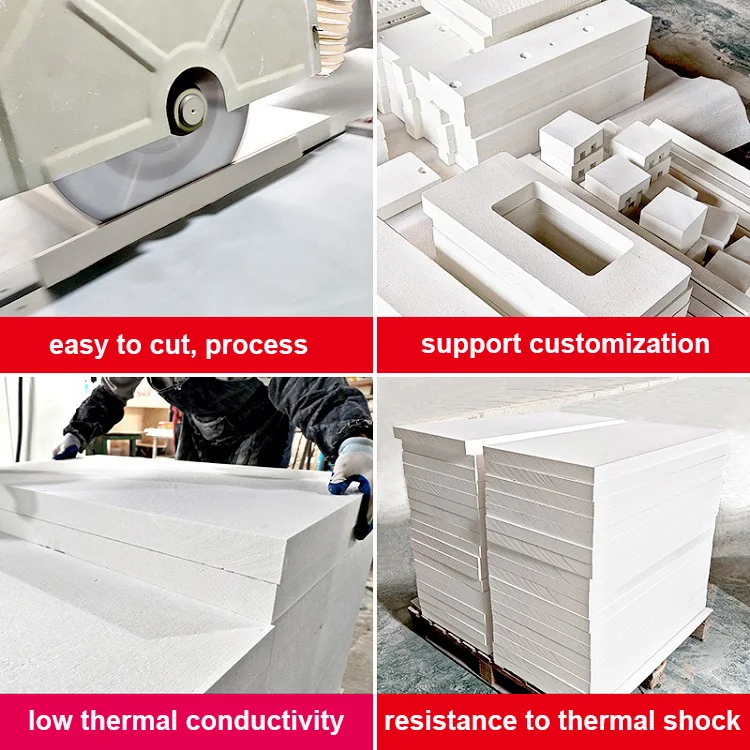

Ceramic fiber board is a high-performance insulating product formed by ceramic fiber and adhesive in vacuum. It is flat, ceramic materials are evenly distributed, and has excellent heat insulation performance. Due to its low thermal conductivity and low heat storage, no inflation during heating can reduce energy cost and cycle time, and protect the refractory surface from thermal shock and chemical attack. Therefore, it is an ideal product for fire resistance, heat insulation and heat insulation.

Features

1.Low heat storage;

2.Resistant to Non-Ferrous Metals;

3.Excellent resistance to thermal shock and chemical attack;

4.Resists oxidation and reduction;

5.High mechanical strength at high temperature;

6.Can be machined, cut and shaped easily

7.High rigidity and light weight

| Standard ceramic fiber blanket - working temperature 1050 ℃ High-alumina ceramic fiber blanket - working temperature 1260 ℃ Zirconia ceramic fiber blanket - working temperature 1350 ℃ Thickness 6-50mm | |||||||

| Type | COM | ST | HP | HA | Zir-Alu | HZ | |

| Classified Temp. | 1100ºC (1983ºF) | 1260ºC (2300ºF) | 1260ºC (2300ºF) | 1360ºC (2480ºF) | 1400ºC (2550ºF) | 1430ºC (2600ºF) | |

| Working Temp. | <1000ºC (2012ºF) | 1050ºC (1922ºF) | 1100ºC (2012ºF) | 1200ºC (2192ºF) | 1200ºC (1192ºF) | 1350ºC (2462ºF) | |

| Color | white | white | white | white | white | white | |

| Density(kg/m3) | 260-320 (16-20lb/ft3) | ||||||

| Linear Shrinkage (%)(24 hrs) | -3 (1000ºC/1832ºF) | ||||||

| Thermal conductivity(W/M.K) | 0.085 (400ºC/752ºF) 0.132 (800ºC/1472ºF) 0.180 (1000ºC/2012ºF) | ||||||

| Compression Strength(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Chemical(%) | Al2O3 | 44 | 46 | 47-49 | 52-55 | 45-46 | 39-40 |

| Al2O3 +SiO2 | 96 | 97 | 99 | 99 | - | - | |

| Al2O3 +SiO2 +ZrO2 | - | - | - | - | - | 99 | |

| ZrO2 | - | - | - | - | 5-7 | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Na2O +K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Size(mm) | 1200*1000mm(47″*40″); 1000*600mm(40″*36″);900*600mm(24″*36″) 20-50mm(1″/2″)thickness | ||||||

|

|

1260 Refractory Ceramic Fiber Board Thermal Insulation Aluminum Silicate Board For Industrial Furnace Images |